Coal Blocks vs. Coal: A Comprehensive Comparison for Informed Decisions

The energy sector relies heavily on coal, a fossil fuel used for power generation, industrial processes, and heating. However, coal comes in various forms, with raw coal and processed coal blocks being two prominent options. Understanding the differences between coal blocks and raw coal is crucial for making informed decisions regarding energy efficiency, environmental impact, and cost-effectiveness. This article provides a comprehensive comparison to help you navigate the complexities of coal utilization.

Understanding Raw Coal

Raw coal, as the name suggests, is the unprocessed form of coal extracted directly from the earth. Its composition varies depending on the mine’s location and geological conditions. Generally, raw coal contains a mixture of combustible matter (carbon, hydrogen, and sulfur), non-combustible matter (ash and moisture), and trace elements. The quality of raw coal is assessed based on parameters like heating value, ash content, sulfur content, and moisture content.

- Heating Value: The amount of heat released when a unit mass of coal is burned completely. Higher heating value indicates better energy content.

- Ash Content: The percentage of non-combustible residue remaining after coal combustion. High ash content reduces the heating value and increases handling and disposal costs.

- Sulfur Content: The amount of sulfur present in coal. Burning high-sulfur coal leads to sulfur dioxide (SO2) emissions, a major air pollutant.

- Moisture Content: The amount of water present in coal. High moisture content reduces the heating value and increases transportation costs.

Raw coal is often cheaper than coal blocks due to the minimal processing involved. However, its inconsistent quality, higher emissions, and handling difficulties make it less desirable for many applications. [See also: Coal Mining Techniques and Environmental Impact]

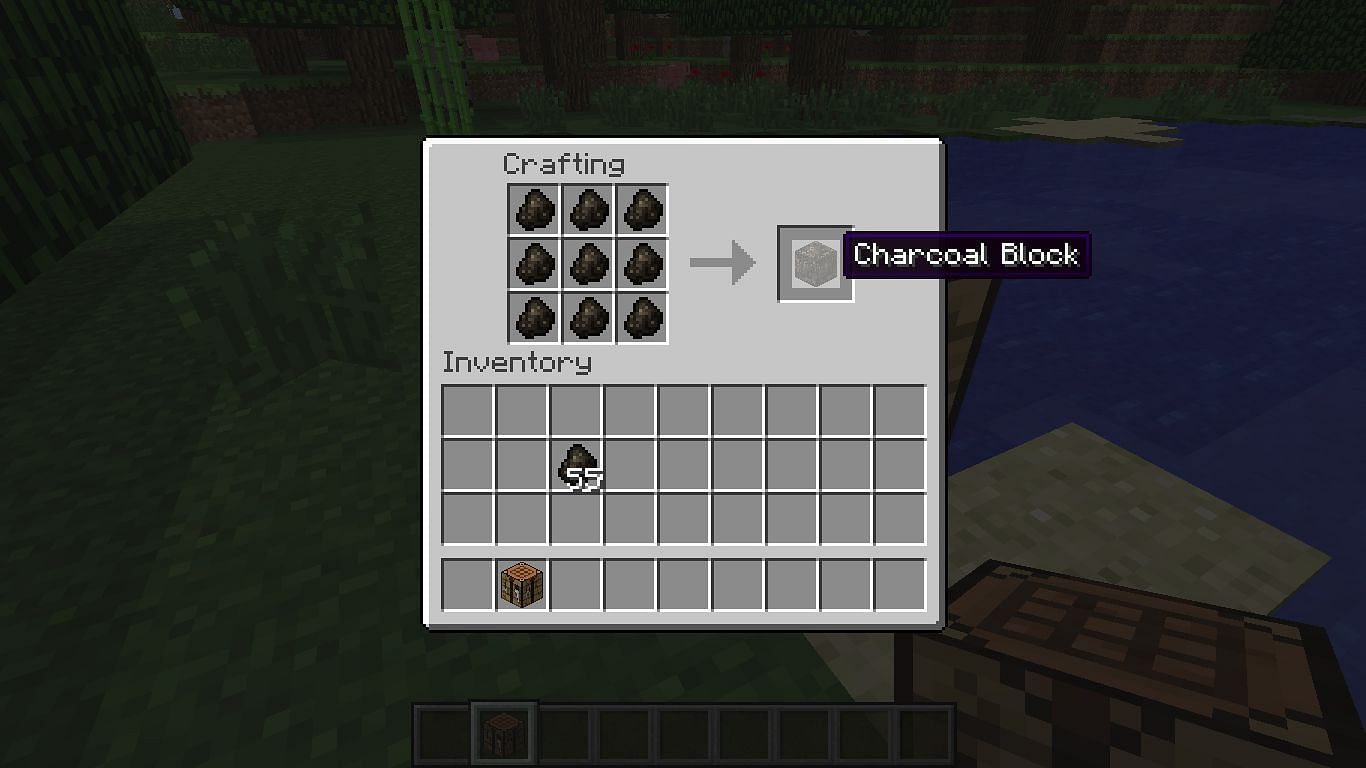

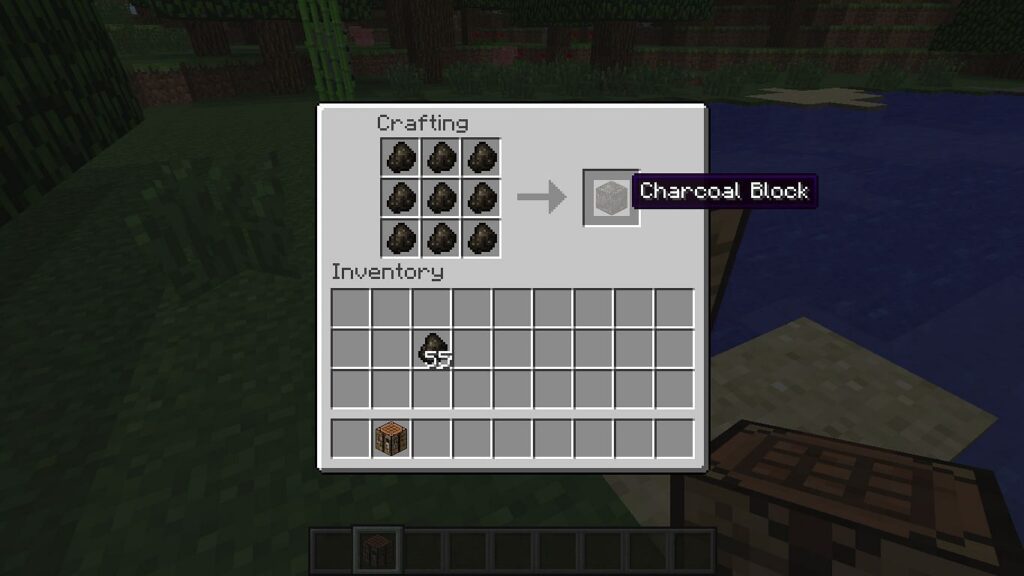

Exploring Coal Blocks

Coal blocks are manufactured by processing raw coal to improve its quality and consistency. The process typically involves crushing, cleaning, and compacting raw coal into uniform shapes and sizes. Binders like starch or clay may be added to improve the structural integrity of the blocks. This processing addresses several drawbacks associated with raw coal.

- Improved Heating Value: Processing removes impurities and concentrates the combustible matter, resulting in a higher and more consistent heating value.

- Reduced Ash Content: Cleaning processes remove a significant portion of the ash-forming minerals, leading to lower ash content and reduced handling costs.

- Lower Sulfur Content: Some processing methods can reduce the sulfur content of coal, leading to lower SO2 emissions.

- Consistent Size and Shape: Uniform coal blocks facilitate easier handling, storage, and feeding into combustion systems.

While coal blocks offer several advantages over raw coal, they come at a higher cost due to the processing involved. The specific properties of coal blocks can be tailored to meet the requirements of different applications. [See also: Clean Coal Technologies and Future Prospects]

Key Differences: Coal Blocks vs. Coal

To summarize, here’s a table highlighting the key differences between raw coal and coal blocks:

| Feature | Raw Coal | Coal Blocks |

|---|---|---|

| Processing | Unprocessed | Processed (Crushed, Cleaned, Compacted) |

| Heating Value | Variable | Higher and More Consistent |

| Ash Content | High | Lower |

| Sulfur Content | Variable | Potentially Lower |

| Moisture Content | High | Lower |

| Size and Shape | Irregular | Uniform |

| Cost | Lower | Higher |

| Handling | Difficult | Easier |

| Emissions | Higher | Lower (Potentially) |

Advantages and Disadvantages

Raw Coal

Advantages:

- Lower initial cost.

- Readily available in many regions.

Disadvantages:

- Inconsistent quality.

- High ash and moisture content.

- Higher sulfur content and emissions.

- Difficult to handle and store.

- Lower heating value compared to coal blocks.

Coal Blocks

Advantages:

- Higher and more consistent heating value.

- Lower ash and moisture content.

- Potentially lower sulfur content and emissions.

- Easier to handle and store due to uniform size and shape.

- Improved combustion efficiency.

Disadvantages:

- Higher initial cost due to processing.

- May require binders, which can add to the overall cost and environmental impact.

Applications of Coal Blocks and Raw Coal

The choice between raw coal and coal blocks depends on the specific application and the priorities of the user.

Raw Coal Applications:

- Large-scale power plants that have the infrastructure to handle raw coal and manage the resulting emissions.

- Industrial processes where cost is the primary concern and environmental regulations are less stringent.

- Certain heating applications where the lower cost outweighs the disadvantages of inconsistent quality and higher emissions.

Coal Blocks Applications:

- Small to medium-sized power plants seeking to improve efficiency and reduce emissions.

- Industrial processes requiring consistent fuel quality and ease of handling.

- Residential and commercial heating applications where cleanliness, convenience, and reduced emissions are important.

- Gasification processes where a uniform feedstock is required.

Environmental Considerations

Both raw coal and coal blocks contribute to greenhouse gas emissions and air pollution when burned. However, coal blocks offer the potential for reduced emissions due to their lower sulfur content and improved combustion efficiency. Furthermore, the uniform size and shape of coal blocks facilitate the use of advanced combustion technologies that can further reduce emissions. [See also: Carbon Capture and Storage Technologies]

The environmental impact of coal extraction and processing must also be considered. Coal mining can lead to habitat destruction, water pollution, and soil erosion. Coal processing can generate wastewater and solid waste. Sustainable coal mining and processing practices are essential to minimize the environmental impact of coal utilization.

Economic Considerations

The economic viability of using raw coal or coal blocks depends on several factors, including the cost of coal, transportation costs, processing costs, and the cost of emission control technologies. While raw coal is generally cheaper upfront, the higher handling costs, lower efficiency, and potential costs associated with emission control can make coal blocks a more cost-effective option in the long run. A thorough cost-benefit analysis is essential to determine the most economical fuel choice for a particular application.

Future Trends in Coal Utilization

The future of coal utilization is likely to be shaped by increasing environmental regulations and the growing demand for cleaner energy sources. Coal-fired power plants are facing increasing pressure to reduce their emissions of greenhouse gases, sulfur dioxide, and other pollutants. As a result, there is a growing interest in clean coal technologies, such as carbon capture and storage, which can significantly reduce the environmental impact of coal combustion. The development of more efficient and environmentally friendly coal blocks is also a key area of research and development.

Conclusion: Making the Right Choice

Deciding whether coal blocks are better than raw coal depends on a variety of factors, including the specific application, environmental regulations, and economic considerations. Coal blocks offer several advantages over raw coal, including higher heating value, lower ash content, and potentially lower emissions. However, they also come at a higher cost. By carefully evaluating the advantages and disadvantages of each option, users can make informed decisions that balance energy efficiency, environmental impact, and cost-effectiveness. The future of coal hinges on adopting cleaner technologies and making responsible choices regarding its utilization, whether it’s in the form of raw coal or processed coal blocks. As the energy landscape evolves, understanding the nuances of coal utilization will be paramount for a sustainable and efficient energy future. The use of coal blocks can be a step toward mitigating some negative impacts associated with traditional coal use. Careful consideration and a holistic approach are essential when comparing coal blocks to raw coal in any energy strategy.