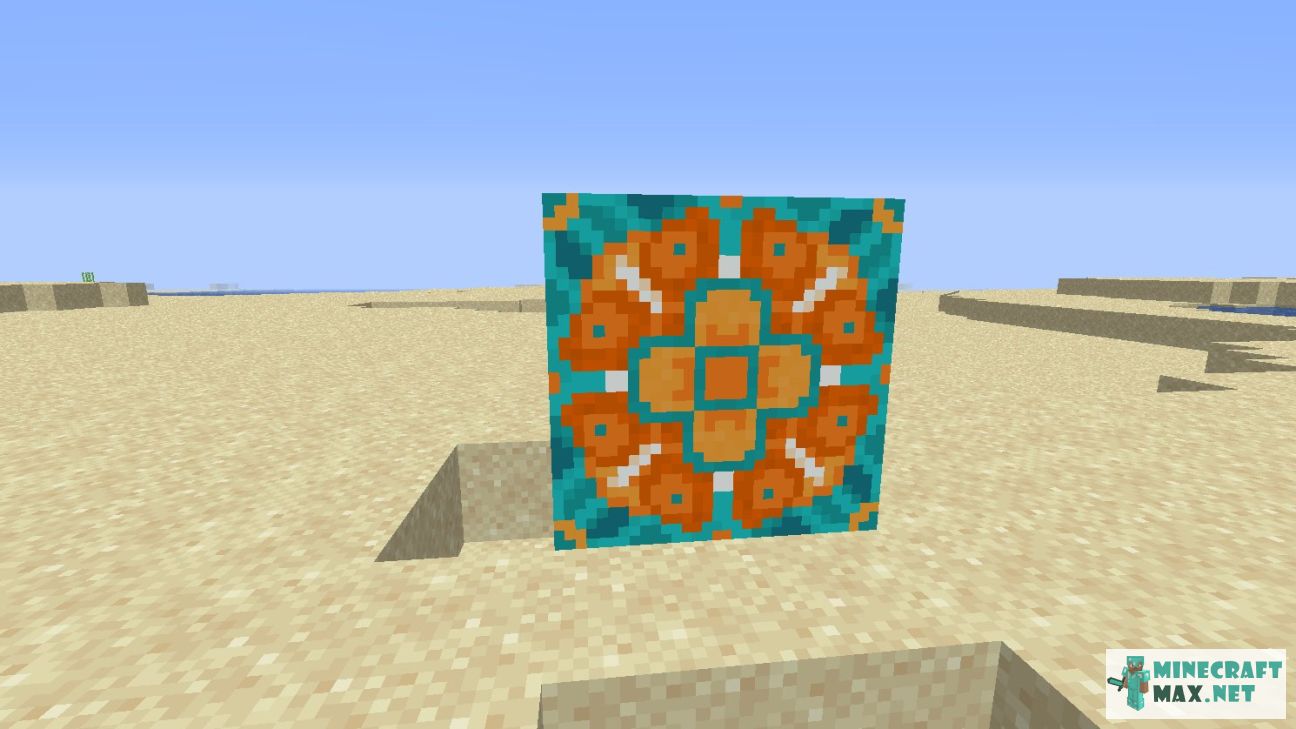

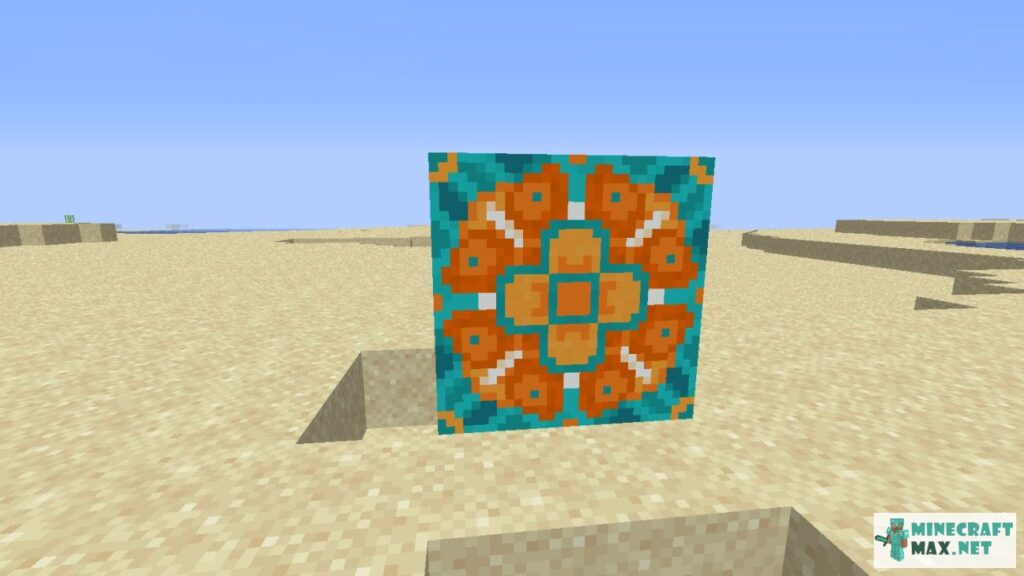

Mastering the Art: How to Place Glazed Terracotta with Precision and Style

Glazed terracotta, with its vibrant colors and durable finish, has been a favored material in architecture and design for centuries. From intricate façade details to eye-catching interior accents, its versatility is undeniable. However, achieving a flawless installation requires careful planning and execution. This comprehensive guide will walk you through the essential steps of how to place glazed terracotta, ensuring a stunning and long-lasting result. Whether you’re a seasoned professional or a DIY enthusiast, understanding the nuances of this material is crucial for a successful project.

Understanding Glazed Terracotta

Before diving into the installation process, it’s important to understand the characteristics of glazed terracotta. Terracotta, meaning “baked earth” in Italian, is a clay-based ceramic. The glazing process involves applying a coating of vitreous substance to the terracotta surface, which is then fired at high temperatures. This creates a hard, non-porous, and often colorful finish. The glazing protects the terracotta from the elements, making it suitable for both interior and exterior applications.

Glazed terracotta comes in various shapes, sizes, and colors. It can be custom-made to fit specific design requirements, allowing for intricate patterns and unique architectural expressions. Common applications include building facades, decorative panels, roofing tiles, and interior wall cladding. Knowing the specific properties of your chosen terracotta is vital for proper installation. Always refer to the manufacturer’s specifications for detailed guidance.

Planning Your Glazed Terracotta Installation

Proper planning is the cornerstone of any successful glazed terracotta project. This phase involves several critical steps, including site assessment, material selection, and design layout.

Assessing the Site

Begin by thoroughly assessing the installation site. Consider the following factors:

- Structural Integrity: Ensure the supporting structure can bear the weight of the glazed terracotta. This is particularly important for exterior applications where the material will be exposed to wind and other environmental factors. Consult with a structural engineer if necessary.

- Substrate Condition: The substrate, or the surface to which the terracotta will be attached, must be clean, dry, and free from any loose debris. Cracks or imperfections should be repaired before installation.

- Weather Conditions: Avoid installing glazed terracotta during extreme weather conditions, such as heavy rain or freezing temperatures. These conditions can affect the adhesion of the mortar or adhesive and compromise the final result.

Selecting the Right Materials

Choosing the appropriate materials is crucial for a durable and aesthetically pleasing installation. Consider the following:

- Mortar or Adhesive: Select a mortar or adhesive specifically designed for use with terracotta. These products are formulated to provide excellent adhesion and flexibility, accommodating the natural expansion and contraction of the material. Epoxy mortars are often preferred for their superior strength and water resistance.

- Grout: Choose a grout that complements the color of the glazed terracotta. Epoxy grouts are highly recommended for their stain resistance and durability, especially in wet environments.

- Fasteners: Depending on the installation method, you may need fasteners such as screws, clips, or anchors. Select fasteners that are compatible with both the terracotta and the supporting structure. Stainless steel fasteners are ideal for exterior applications due to their corrosion resistance.

Creating a Detailed Layout

A well-defined layout is essential for achieving a precise and visually appealing installation. Create a detailed plan that outlines the placement of each terracotta piece. Consider the following:

- Measurements: Take accurate measurements of the installation area. Use a laser level or other precision tools to ensure that the layout is straight and level.

- Spacing: Determine the appropriate spacing between the terracotta pieces. Consistent spacing is crucial for a uniform appearance. Use spacers to maintain consistent grout lines.

- Cutting: If cutting is required, use a wet saw with a diamond blade specifically designed for cutting terracotta. This will minimize chipping and ensure clean, precise cuts.

Step-by-Step Guide to Placing Glazed Terracotta

Now that you have a solid plan in place, it’s time to begin the installation process. Follow these steps for a successful outcome:

Preparing the Substrate

The substrate must be properly prepared to ensure adequate adhesion. Clean the surface thoroughly with a wire brush and a mild detergent solution. Rinse with clean water and allow to dry completely. Repair any cracks or imperfections with a suitable patching compound. Apply a primer to the substrate to improve adhesion, especially on porous surfaces.

Applying the Mortar or Adhesive

Using a notched trowel, apply a generous layer of mortar or adhesive to the back of the terracotta piece. The size of the notches on the trowel will depend on the size and weight of the terracotta. Follow the manufacturer’s recommendations for the appropriate trowel size and application technique. Ensure that the entire back surface is covered with mortar or adhesive.

Positioning the Terracotta

Carefully position the terracotta piece onto the substrate. Press firmly to ensure good contact with the mortar or adhesive. Use a level to check that the terracotta is properly aligned. Insert spacers between the terracotta pieces to maintain consistent grout lines. For larger pieces, you may need to use temporary supports to hold them in place while the mortar or adhesive cures.

Cutting Terracotta

Cutting glazed terracotta requires precision and the right tools. A wet saw with a diamond blade is essential for achieving clean cuts without chipping or cracking the material. Always wear safety glasses and gloves when cutting terracotta. Measure and mark the cutting line accurately. Feed the terracotta slowly and steadily into the saw, allowing the blade to do the work. Avoid applying excessive pressure, which can cause the terracotta to break.

Grouting the Joints

Once the mortar or adhesive has cured completely, it’s time to grout the joints between the terracotta pieces. Remove the spacers and clean the grout lines thoroughly. Mix the grout according to the manufacturer’s instructions. Apply the grout using a grout float, working it into the joints at a 45-degree angle. Remove excess grout with a damp sponge, being careful not to disturb the grout in the joints. Allow the grout to cure according to the manufacturer’s instructions.

Cleaning and Sealing

After the grout has cured, clean the surface of the glazed terracotta with a mild detergent solution. Rinse with clean water and allow to dry completely. Apply a sealer specifically designed for terracotta to protect the surface from stains and moisture. Follow the manufacturer’s instructions for application and maintenance. Regular cleaning and sealing will help to preserve the beauty and longevity of your glazed terracotta installation.

Advanced Techniques for Glazed Terracotta Installation

For more complex projects, consider these advanced techniques:

Anchoring Systems

For large-scale exterior installations, anchoring systems provide additional support and stability. These systems typically involve attaching metal brackets or clips to the back of the terracotta pieces and securing them to the supporting structure. Anchoring systems are essential for ensuring the long-term performance of the installation, especially in areas with high winds or seismic activity.

Rain Screen Systems

Rain screen systems are designed to protect buildings from moisture damage by creating an air gap between the terracotta cladding and the building’s exterior wall. This air gap allows for ventilation, which helps to dry out any moisture that penetrates the cladding. Rain screen systems are particularly effective in preventing mold growth and prolonging the lifespan of the building.

Custom Fabrication

For unique architectural designs, custom-fabricated glazed terracotta pieces can be created to meet specific requirements. This allows for intricate patterns, complex shapes, and personalized color schemes. Custom fabrication requires close collaboration between the architect, the manufacturer, and the installation team to ensure that the final product meets the design intent.

Maintaining Your Glazed Terracotta Installation

Proper maintenance is essential for preserving the beauty and longevity of your glazed terracotta installation. Follow these tips:

- Regular Cleaning: Clean the surface regularly with a mild detergent solution to remove dirt and grime. Avoid using harsh chemicals or abrasive cleaners, which can damage the glazing.

- Sealing: Reapply sealer periodically to protect the surface from stains and moisture. The frequency of sealing will depend on the type of sealer used and the exposure to the elements.

- Inspecting: Inspect the installation regularly for any signs of damage, such as cracks or loose pieces. Repair any damage promptly to prevent further deterioration.

Troubleshooting Common Issues

Even with careful planning and execution, problems can sometimes arise during or after the installation process. Here are some common issues and how to address them:

- Efflorescence: Efflorescence is a white, powdery deposit that can appear on the surface of glazed terracotta. It is caused by salts in the mortar or substrate migrating to the surface and crystallizing. Remove efflorescence with a solution of water and vinegar.

- Cracking: Cracking can occur due to thermal expansion and contraction, improper installation, or structural movement. Small cracks can be repaired with a patching compound. Larger cracks may require the replacement of the affected terracotta pieces.

- Loose Pieces: Loose pieces can be caused by inadequate adhesion or damage to the mortar or adhesive. Remove the loose pieces and clean the substrate thoroughly. Reinstall the pieces with fresh mortar or adhesive.

How to place glazed terracotta effectively is a blend of art and science. By understanding the material properties, planning meticulously, and executing with precision, you can create a stunning and durable installation that will enhance the beauty of any space. Remember to always consult with professionals when needed and follow the manufacturer’s guidelines for the best results. [See also: Terracotta Tile Installation Guide] [See also: Choosing the Right Mortar for Terracotta] [See also: Sealing Terracotta for Long-Term Protection]

Glazed terracotta offers a unique blend of aesthetic appeal and durability, making it a versatile choice for various design applications. Mastering the techniques of how to place glazed terracotta allows you to unlock its full potential and create stunning architectural features that stand the test of time. With proper planning, execution, and maintenance, your glazed terracotta installation will remain a source of pride and admiration for years to come.

The process of learning how to place glazed terracotta involves understanding its unique characteristics, selecting appropriate materials, and employing precise installation techniques. Whether you are working on a small-scale interior project or a large-scale exterior facade, the principles remain the same: meticulous planning, careful execution, and diligent maintenance are key to achieving a flawless and long-lasting result. By following the guidelines outlined in this article, you can confidently embark on your glazed terracotta project and create a stunning architectural masterpiece.