Understanding Auger Reach: Maximizing Efficiency and Safety in Drilling Operations

In the realm of construction, geotechnical engineering, and environmental drilling, the term “auger reach” holds significant importance. It refers to the maximum depth or distance that an auger drilling tool can effectively penetrate and operate. Understanding auger reach is crucial for planning projects, selecting appropriate equipment, and ensuring both efficiency and safety on the job site. This article delves into the various aspects of auger reach, exploring its determinants, limitations, and best practices for optimizing its use.

What is Auger Reach?

At its core, auger reach defines the operational capability of an auger. An auger is a drilling device featuring a helical screw blade, or flighting, used to remove drilled material. The auger reach is the maximum depth an auger can penetrate below the surface, or, in some applications, the horizontal distance it can extend. Several factors influence this reach, including the type of auger, the power of the drilling rig, and the soil conditions.

Auger reach is not just a matter of physical extension. It encompasses the ability to effectively extract material and maintain the stability of the borehole. If an auger is pushed beyond its effective reach, it can lead to reduced drilling efficiency, increased risk of equipment damage, and potential collapse of the borehole.

Factors Influencing Auger Reach

Several key factors determine the maximum auger reach achievable in a specific drilling operation:

- Auger Type and Design: Different auger types are designed for varying soil conditions and depths. Continuous flight augers, for instance, are efficient for drilling in soft to medium soils, while hollow stem augers are used for soil sampling and monitoring well installation. The design of the auger, including the diameter and pitch of the flights, directly impacts its ability to penetrate and remove material.

- Drilling Rig Power and Torque: The power of the drilling rig is essential for overcoming the resistance of the soil. Higher torque capabilities allow the auger to penetrate denser materials and maintain consistent drilling speed. Insufficient power can lead to stalling and reduced auger reach.

- Soil Conditions: The type and composition of the soil significantly affect drilling efficiency. Soft soils like sand and silt are easier to drill through, allowing for greater auger reach. Conversely, dense clay, gravel, or rock formations present greater resistance and limit the achievable depth. [See also: Geotechnical Site Investigation Techniques]

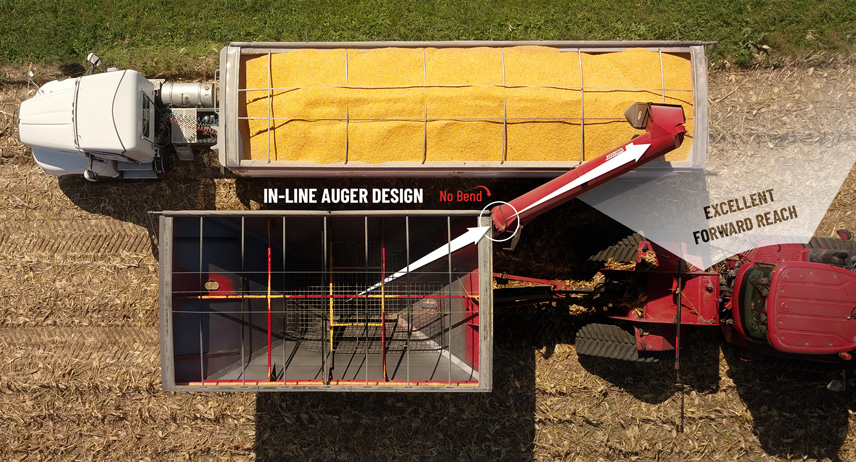

- Auger Extension and Stability: Adding extensions to the auger string can increase its reach, but it also introduces challenges related to stability. Longer auger strings are more prone to bending and vibration, which can reduce drilling efficiency and increase the risk of equipment failure. Maintaining a stable and aligned auger string is crucial for maximizing reach.

- Borehole Stability: The stability of the borehole is critical for maintaining auger reach. In unstable soils, the borehole can collapse, hindering the auger’s ability to penetrate further. Techniques like using drilling mud or casing can help stabilize the borehole and extend the achievable reach.

Types of Augers and Their Reach Capabilities

The type of auger used directly impacts the achievable auger reach. Here’s a brief overview of common auger types and their general capabilities:

- Continuous Flight Augers: These are the most common type of augers, used for general drilling purposes. They are efficient for drilling in soft to medium soils and can achieve moderate reach depths, typically up to 100 feet depending on soil conditions and rig power.

- Hollow Stem Augers: These augers have a hollow center that allows for soil sampling and monitoring well installation. Their reach is generally limited compared to continuous flight augers due to their design, typically reaching depths of up to 50 feet.

- Bucket Augers: Bucket augers are used for drilling large-diameter boreholes. They have a bucket-like cutting head that collects the drilled material. Their reach can vary depending on the bucket size and soil conditions, but they are generally used for shallower depths, typically up to 30 feet.

- Rock Augers: These augers are designed for drilling through hard rock formations. They feature hardened cutting teeth and are capable of penetrating dense materials. Their reach is often limited by the hardness of the rock and the power of the drilling rig.

Optimizing Auger Reach for Efficiency and Safety

Maximizing auger reach while maintaining efficiency and safety requires careful planning and execution. Here are some best practices to consider:

- Conduct a Thorough Site Investigation: Before starting any drilling operation, it’s essential to conduct a thorough site investigation to understand the soil conditions. This includes performing soil borings and laboratory testing to identify soil types, density, and groundwater levels. This information will help determine the appropriate auger type and drilling parameters.

- Select the Right Auger and Drilling Rig: Choose an auger that is specifically designed for the anticipated soil conditions and drilling depth. Ensure that the drilling rig has sufficient power and torque to overcome the resistance of the soil. Using the wrong equipment can lead to reduced efficiency and increased risk of equipment damage.

- Maintain Proper Auger Alignment: Maintaining proper alignment of the auger string is crucial for maximizing auger reach and preventing bending or vibration. Use stabilizers and centralizers to keep the auger string aligned and centered in the borehole.

- Control Drilling Speed and Pressure: Adjust the drilling speed and pressure based on the soil conditions. Excessive drilling speed or pressure can lead to stalling and reduced efficiency. Monitor the drilling parameters and make adjustments as needed.

- Use Drilling Fluids or Casing: In unstable soils, consider using drilling fluids or casing to stabilize the borehole and prevent collapse. Drilling fluids can help lubricate the auger and remove cuttings, while casing can provide structural support to the borehole walls.

- Regularly Inspect and Maintain Equipment: Regularly inspect and maintain the auger and drilling rig to ensure they are in good working condition. Replace worn or damaged parts promptly to prevent equipment failure and maintain optimal performance.

- Implement Safety Protocols: Adhere to strict safety protocols to prevent accidents and injuries. This includes wearing appropriate personal protective equipment (PPE), maintaining a safe working distance from the drilling rig, and following all relevant safety regulations.

Challenges and Limitations of Auger Reach

Despite careful planning and execution, several challenges and limitations can affect auger reach:

- Hard Rock Formations: Drilling through hard rock formations can significantly limit auger reach. Specialized rock augers and drilling techniques may be required to penetrate these materials.

- Groundwater: High groundwater levels can destabilize the borehole and reduce drilling efficiency. Dewatering techniques may be necessary to lower the groundwater level and improve auger reach.

- Obstructions: Underground obstructions, such as buried utilities or debris, can impede drilling progress and limit auger reach. Thorough site investigation and utility locating are essential to identify and avoid these obstructions.

- Equipment Limitations: The physical limitations of the auger and drilling rig can also affect auger reach. Longer auger strings are more prone to bending and vibration, while insufficient rig power can limit the ability to penetrate dense materials.

Advancements in Auger Technology

Ongoing advancements in auger technology are continuously improving auger reach and drilling efficiency. These advancements include:

- Improved Auger Designs: Manufacturers are developing new auger designs that offer improved penetration rates and stability. These designs often incorporate advanced cutting teeth and flighting configurations.

- More Powerful Drilling Rigs: Drilling rig manufacturers are producing more powerful rigs with higher torque capabilities. These rigs can overcome the resistance of denser soils and extend auger reach.

- Automated Drilling Systems: Automated drilling systems are becoming increasingly common, offering improved precision and control. These systems can optimize drilling parameters and maximize auger reach.

- Real-Time Monitoring: Real-time monitoring systems provide operators with valuable data on drilling parameters, such as torque, pressure, and depth. This information allows for informed decision-making and optimized drilling performance.

Conclusion

Understanding auger reach is essential for planning and executing successful drilling operations. By considering the various factors that influence reach, selecting the appropriate equipment, and implementing best practices, engineers and contractors can maximize efficiency, minimize risks, and achieve their project goals. As auger technology continues to advance, the potential for even greater auger reach and drilling efficiency will undoubtedly emerge, further enhancing the capabilities of the construction and geotechnical engineering industries. The careful consideration of soil conditions, equipment capabilities, and safety protocols will remain paramount in ensuring successful and safe drilling operations.